Triggered by the surge in demand for PPE during COVID-19, Vancouver Coastal Health took swift action to improve the delivery of supplies to community sites on the frontlines.

VCH’s Contract Management Team teamed up with Restock Smart Marketplace to engineer a more centralized ordering process to ensure that all community sites had adequate PPE.

The adoption of a smart ordering solution resulted in a dramatic improvement in efficiency, improved transparency for all stakeholders, real-time reporting and improved command and control of the entire supply chain. With this bold step they ensured rapid and efficient distribution of essential PPE to community sites.

Clear results were seen across the supply chain

Staff Efficiency

The number of seconded staff assigned to the pandemic helpdesk was decreased by a factor of six.

Priority Orders

Orders could be prioritized based on need and emergency PPE was delivered to outbreak sites within four hours of an order being placed.

Supply Chain Oversight

VCH gained complete supply chain oversight plus the flexibility to manage and optimize it.

Instant Reporting

Accurate inventory and forecasting reports demanded by the BC Ministry of Health could be generated instantaneously instead of taking days.

Inventory Insights

Healthcare leaders now had up-to-date information on how much PPE was available across the different sites under VCH; ensuring that PPE supply was distributed equitably, adequately and without the risk of stockpiling.

Automated Authorization

The authorization of orders was largely automated, depending on the Site, the User, the Product Category or even the specific Product type.

Consolidated Ordering

VCH’s Contract Management Team gained the ability to submit one consolidated order with PHSA rather than many individual orders; reducing the additional load on VCH’s finance department as well as the PHSA helpdesk.

Reduced training and improved system adoption

With a familiar online shopping experience, the system was easy to use not just for supply chain managers, but for the staff at the point-of-care sites whose job it was to procure PPE. This user-friendliness reduced the need for training staff and sped up system adoption.

VCH worked with Restock Smart Marketplace to develop a solution that was significantly more streamlined than the standard workflow typically found in a healthcare supply chain.

The objectives for the new solution were three-fold:

- It needed to address the critical operational need to quickly and efficiently distribute PPE to hundreds of point-of-care sites; particularly those dealing with an active COVID-19 outbreak.

- It needed to have the capacity – without tying up staff time – to meet a whole new level of daily reporting expectations demanded by provincial and federal health ministries.

- It needed to provide the oversight and the flexibility to manage a tight supply chain (i.e. the balancing act whereby supply chain managers strive to supply a site with enough ‘on hand’ PPE to meet their needs while not tying up cash in oversupply).

These objectives were practically impossible in a paper-based distribution model and required six times as many seconded staff as the new, more streamlined solution.

Supply Chain 2.0: From a world of faxes, emails, spreadsheets and helpdesks, VCH switched to an intelligent, online ordering system.

A more centralized ordering process ensured that all VCH community sites had adequate PPE. The illuminating new system provided a dramatic improvement in efficiency, improved transparency for all stakeholders, better control and real-time reporting.

How it works

-

A need arises

Staff at the 800 point-of-care sites could now skip the PDF, saving themselves time and eliminating duplicate effort. -

Online ordering

Staff could now place orders 24/7 via an online ordering portal (similar to Amazon) that was easy to keep updated with product changes. -

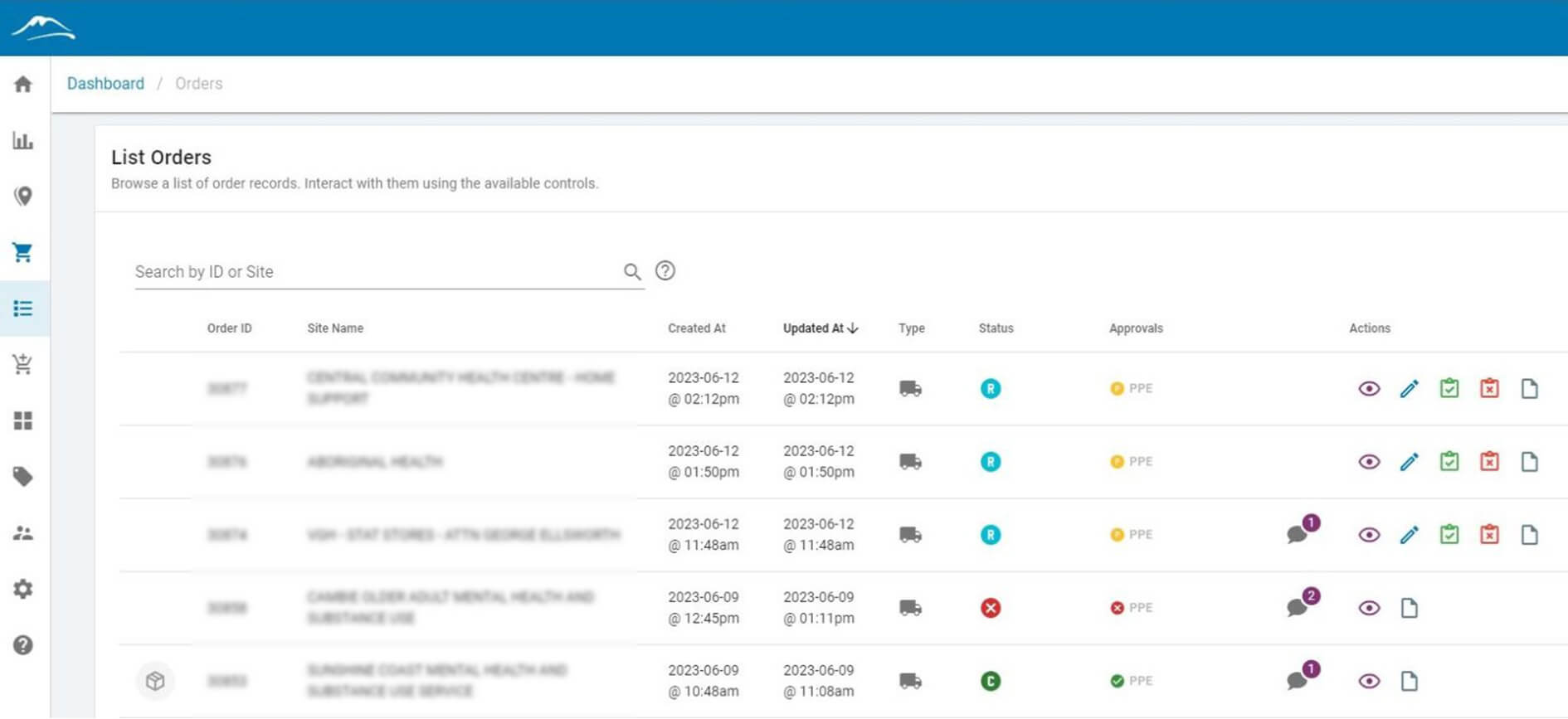

Approvals and controls

Automated approval rules ensured that sites, entire roles or even individual users could only order products that they were authorized to. Managerial ‘contract advisors’ could also manually approve orders. -

Smooth fulfillment

Using data links, the 700 orders per month would go straight into the warehouse’s systems, speeding up dispatchment, eliminating human errors and saving data entry time. -

Dedicated delivery

Orders were trackable all the way from order submitted to package delivered.

-

Real-time reporting

Reports that used to take days to compile now just took a few clicks.

Why a Smart Ordering System?

-

Unprecedented Demand

During the early stages of the pandemic, the surge in demand for personal protective equipment (PPE) and other supplies overwhelmed VCH’s existing distribution methods. At the start of the pandemic, VCH point-of-care sites covered by Provincial Health Services Authority (PHSA) would individually request PPE supplies directly from the PHSA. However, without any centralized coordination, disparities occurred where some point-of-care sites had too much PPE while others had none. Some of VCH’s sites – and hundreds of other community sites not supported by PHSA – even resorted to third-party vendors to acquire PPE supplies; resulting in higher costs with less assurance of quality. Managers lacked the necessary tools to answer basic supply chain questions, such as “How much PPE do we have on hand at each individual site?”. The situation – perhaps only frustrating during normal times – was untenable as the pandemic swept over the province. -

Public & Political Pressure

Adrian Dix (BC Minister of Health) and Bonnie Henry (Provincial Health Officer) faced an onslaught of media interest and faced an anxious public that demanded answers as to how the province was dealing with the ballooning pandemic. The responsibility on them to effectively and accurately communicate to the general public naturally trickled down as pressure on provincial health authorities to provide timely reports on various matters; including current PPE inventory levels, forecasted needs and the requisite distribution plans. Without a centralized procurement and ordering system, the reports demanded by politicians and health leaders were extremely labour intensive and, in some cases, impossible to produce. -

An Innovative Solution Needed

To address these reporting demands and to ensure equitable access to PPE across VCH, a more organized and coordinated system was required. The safe decision would have been to throw more money and people at the problem, but VCH’s leadership pushed hard for a more elegant approach. The Head of the VCH Contract Management Office collaborated closely with PHSA to streamline PPE procurement for the entire organization. They also supported the Regional Emergency Operations Centre (REOC) in acquiring offshore PPE when necessary. Additionally, VCH explored partnerships across British Columbia to potentially repurpose local manufacturing for PPE production. -

Smart Ordering System

As part of their efforts, VCH struck up a partnership with Silverback Systems; a SaaS company based in British Columbia that provides order and supply chain management solutions for the public sector. Silverback Systems designed and implemented a centralized ordering and inventory system for VCH that significantly improved the distribution of PPE to individual point-of-case sites. Silverback’s “Smart Ordering System” is similar to the ‘Amazon marketplace’, but one that can be customized for organizations in which greater control is a critical requirement. For example, health authorities such as VCH value the ability to only allow authorized people to order a specific product approved for use at their site.

In the 3 years since VCH adopted Silverback Systems, over 16,000 individual orders have gone through the Smart Ordering System. That’s approximately 5,400 orders per year and represents an astounding 1.8 million units.

These numbers speak to the system’s reliability, but they do not speak to the payoff received by Vancouver Coastal Health in return for the investment made in Silverback Systems.

In the case of VCH, the return on investment on Silverback Systems can be measured in concrete results; such as greater efficiency, less staff required, tighter cost controls, faster fulfillment, predictive ordering, etc. There are also intangible benefits; such as the ability to quickly satisfy a health minister’s demand for a daily inventory report or the advantage of using real-world data to perfectly forecast supply needs. The most crucial intangible benefit may be greater organizational resilience; the fact that VCH is better prepared for the next crisis.

The most interesting takeaway is not about the technology or its benefits, but rather about the problem-solving people at VCH who would not accept the status quo during a pandemic. They are living and breathing examples of VCH’s values of “learning everyday and caring for everyone”. Those of us under their shield of care are all the better for it.